Disclosure: we may get a commission from qualifying purchases made through affiliate links in this post but at no additional cost to you.

The Keyword Protocol 2000 (Code KWP2000) is a standardized communication protocol used in automotive diagnostics. It facilitates interactions between diagnostic tools and vehicle electronic control units (ECUs), enabling tasks such as reading fault codes, monitoring real-time data, and reprogramming ECUs. Understanding KWP2000 is essential for automotive professionals and enthusiasts aiming to maintain and troubleshoot modern vehicles effectively.

What Is the KWP2000 Code?

The KWP2000 code, or Keyword Protocol 2000, is a standardized communication protocol used in automotive diagnostics. Established under the International Organization for Standardization (ISO) as ISO 14230, KWP2000 facilitates communication between a vehicle’s electronic control units (ECUs) and external diagnostic tools, enabling tasks such as reading fault codes, monitoring real-time data, and reprogramming ECUs .

Key Characteristics of KWP2000

- Standardization: KWP2000 is standardized by ISO, ensuring interoperability between diagnostic tools and vehicle ECUs across different manufacturers.

- Communication Layers: The protocol defines layers 3 to 7 of the OSI model, covering the transport protocol and diagnostic services.

- Physical Layers: KWP2000 can operate over different physical layers:

- K-Line (ISO 9141): A single-wire, bidirectional communication interface with data rates between 1.2 and 10.4 kilobaud. It requires specific wake-up sequences, such as the 5-baud initialization or fast initialization, to establish communication.

- CAN (ISO 11898): A multi-master, message-oriented protocol allowing higher data rates up to 1 Mbit/s. KWP2000 over CAN is implemented using ISO 15765, which defines the transport protocol for diagnostic communication.

- K-Line (ISO 9141): A single-wire, bidirectional communication interface with data rates between 1.2 and 10.4 kilobaud. It requires specific wake-up sequences, such as the 5-baud initialization or fast initialization, to establish communication.

Diagnostic Services Offered by KWP2000

KWP2000 provides a range of diagnostic services, including:

- Reading and Clearing Diagnostic Trouble Codes (DTCs): Allows technicians to identify and reset fault codes stored in ECUs.

- Real-Time Data Monitoring: Enables observation of live sensor data for analysis and troubleshooting.

- ECU Identification: Retrieves information about the ECU, such as part numbers and software versions.

- Actuator Testing: Facilitates the activation of specific components (e.g., fuel injectors) to verify their functionality.

- ECU Programming: Supports reprogramming or updating the software within ECUs .

Applications and Relevance

KWP2000 has been widely adopted in the automotive industry, particularly by European manufacturers such as Volkswagen, Audi, BMW, and Mercedes-Benz, for vehicles produced from the late 1990s to the mid-2010s. While newer protocols like Unified Diagnostic Services (UDS) are becoming more prevalent, KWP2000 remains relevant for diagnosing and maintaining older vehicles .

Understanding the KWP2000 code is essential for automotive professionals and enthusiasts working with vehicles that utilize this protocol. Its comprehensive diagnostic capabilities continue to make it a valuable tool in the field of automotive diagnostics.

How KWP2000 Works: Communication Layers and Protocols

The Keyword Protocol 2000 (KWP2000), standardized as ISO 14230, is a communication protocol used in automotive diagnostics. It facilitates interactions between diagnostic tools and vehicle electronic control units (ECUs), enabling tasks such as reading fault codes, monitoring real-time data, and reprogramming ECUs. Understanding how KWP2000 operates across various communication layers is essential for effective vehicle diagnostics.

Mapping KWP2000 to the OSI Model

KWP2000 aligns with the Open Systems Interconnection (OSI) model, which standardizes communication functions into seven layers. The protocol primarily encompasses the following layers:

- Physical Layer (Layer 1): Defines the physical connection between devices.

- Data Link Layer (Layer 2): Manages node-to-node data transfer, including error detection and correction.

- Application Layer (Layer 7): Provides diagnostic services and interfaces directly with diagnostic applications.

In some implementations, KWP2000 also covers the Session Layer (Layer 5), managing the initiation, maintenance, and termination of communication sessions.

Physical Layer: K-Line and CAN Interfaces

KWP2000 supports two primary physical layer interfaces:

K-Line (ISO 9141-2)

The K-Line is a single-wire, bidirectional serial communication line operating at baud rates between 1.2 and 10.4 kbps. An optional L-Line may be used for wake-up signaling. Communication over K-Line requires specific initialization sequences:

- 5-Baud Wake-Up: The tester sends a 5-baud address byte to initiate communication.

- Fast Initialization: A quicker method involving specific timing sequences on the K-Line.

These initialization methods are critical for establishing communication with the ECU over the K-Line.

CAN (Controller Area Network – ISO 11898)

KWP2000 can also operate over the CAN bus, offering higher data rates up to 1 Mbps. When implemented over CAN, KWP2000 typically uses the ISO 15765-2 transport protocol, which handles message segmentation and reassembly. Unlike K-Line, CAN-based communication does not require special wake-up sequences, simplifying the initialization process.

Data Link Layer: Message Framing and Error Handling

The Data Link Layer in KWP2000 is responsible for framing messages, managing data flow, and ensuring reliable transmission. Key functions include:

- Message Framing: Constructing messages with appropriate headers and checksums.

- Error Detection: Identifying and handling transmission errors.

- Flow Control: Managing the rate of data transmission to prevent buffer overflows.

These mechanisms ensure that diagnostic messages are accurately transmitted and received between the tester and ECU.

Application Layer: Diagnostic Services

At the Application Layer, KWP2000 defines a set of diagnostic services that allow diagnostic tools to interact with ECUs. These services include:

- Reading Diagnostic Trouble Codes (DTCs): Retrieving stored fault codes from the ECU.

- Clearing DTCs: Erasing fault codes after repairs are made.

- Data Monitoring: Accessing real-time sensor data for analysis.

- ECU Programming: Updating or reprogramming the ECU’s software.

These services enable comprehensive diagnostics and maintenance of vehicle systems.

Key Features and Capabilities of KWP2000

The code KWP2000 (Keyword Protocol 2000), standardized as ISO 14230, is a pivotal communication protocol in automotive diagnostics. It facilitates seamless interaction between diagnostic tools and a vehicle’s Electronic Control Units (ECUs), enabling a range of diagnostic and reprogramming functions. Below is an in-depth exploration of its core features and capabilities:

1. Comprehensive Diagnostic Services

KWP2000 defines a suite of diagnostic services that allow for detailed vehicle analysis:

- Reading Diagnostic Trouble Codes (DTCs): Retrieve stored fault codes to identify issues within various vehicle systems.

- Clearing DTCs: Erase fault codes post-repair to reset the system.

- Reading Freeze Frame Data: Access snapshots of vehicle parameters at the time a fault occurred.

- Reading Sensor Data: Monitor real-time data from various sensors for performance assessment.

- Actuator Testing: Activate specific components (e.g., fuel injectors, relays) to verify their operation.

- ECU Identification: Retrieve information such as ECU part numbers, software versions, and serial numbers.

- ECU Reset: Command the ECU to perform a reset, useful after certain maintenance procedures.

These services are identified by unique Service IDs, facilitating structured communication between diagnostic tools and ECUs.

2. Flexible Communication Layers

KWP2000 operates over multiple physical layers, enhancing its adaptability:

- K-Line (ISO 9141): A single-wire, bidirectional serial communication line commonly used in older vehicles.

- CAN (Controller Area Network – ISO 11898): A faster, multi-master communication protocol prevalent in modern vehicles.

The protocol’s ability to function over both K-Line and CAN allows it to be utilized across a broad spectrum of vehicle models and years.

3. Standardized Protocol Structure

As an ISO-standardized protocol, KWP2000 ensures consistency and interoperability:

- Keyword-Based Communication: Utilizes predefined keywords and data formats for encoding diagnostic requests and responses.

- Layered Architecture: Covers layers 3 to 7 of the OSI model, encompassing the network to application layers.

This standardization promotes reliable communication between diverse diagnostic tools and vehicle ECUs.

4. ECU Reprogramming and Flashing

Beyond diagnostics, KWP2000 supports ECU reprogramming capabilities:

- Firmware Updates: Facilitates updating ECU software to improve performance or address issues.

- Calibration Data Modification: Allows for adjustments to parameters like fuel injection timing and idle speed.

- Configuration Parameter Changes: Enables customization of ECU settings to suit specific requirements.

These functions are crucial for manufacturers and service centers aiming to maintain or enhance vehicle performance.

5. Support for Remote Activation of Routines

KWP2000 includes services for remotely activating routines within the ECU:

- Start/Stop Routine Services: Initiate or terminate specific routines, such as self-tests or adaptations.

- Request Result Services: Obtain the outcome of executed routines for analysis.

This feature enables advanced diagnostic procedures and functional verifications without direct physical intervention.

6. Input/Output Control Services

The protocol allows for manipulation of ECU inputs and outputs:

- Signal Simulation: Override actual sensor inputs with simulated signals for testing purposes.

- Actuator Control: Directly command actuators to assess their response and functionality.

These services are instrumental in pinpointing faults within specific components or circuits.

7. Efficient Data Transmission

KWP2000 supports efficient data handling mechanisms:

- Variable Byte Length Messages: Accommodates messages of varying lengths, enhancing flexibility.

- Transport Protocol Integration: Utilizes transport protocols like ISO TP (ISO 15765-2) for message segmentation and reassembly over CAN networks.

This efficiency ensures reliable and swift communication between diagnostic tools and ECUs.

8. Versatility Across Vehicle Systems

KWP2000’s comprehensive services make it applicable to various vehicle systems:

- Engine and Transmission: Monitor and adjust performance parameters.

- Chassis and Body Electronics: Diagnose and configure systems like ABS, airbags, and lighting.

- Comfort and Convenience Features: Customize settings for climate control, infotainment, and more.

This versatility underscores the protocol’s value in holistic vehicle diagnostics and customization.

KWP2000 vs. OBD2: Understanding the Differences

In the realm of automotive diagnostics, understanding the distinctions between code KWP2000 and OBD2 is crucial for effective vehicle maintenance and repair.

Overview

- OBD2 (On-Board Diagnostics II): A standardized system mandated in many countries, OBD2 provides a universal interface for monitoring and diagnosing vehicle emissions and performance. It utilizes various communication protocols, including ISO 9141, ISO 14230 (KWP2000), and ISO 15765 (CAN), depending on the vehicle’s make and model.

- KWP2000 (Keyword Protocol 2000): Defined by ISO 14230, KWP2000 is a communication protocol used within the OBD2 framework. It facilitates detailed interactions between diagnostic tools and vehicle ECUs, allowing for advanced diagnostics and control .

Key Differences

- Communication Protocols:

- OBD2: Encompasses multiple protocols, including KWP2000, and selects the appropriate one based on the vehicle’s design.

- KWP2000: Specifically operates over the K-Line or CAN bus, depending on the implementation, and requires specific initialization sequences for communication.

- OBD2: Encompasses multiple protocols, including KWP2000, and selects the appropriate one based on the vehicle’s design.

- Data Transmission Speed:

- OBD2: When using the CAN protocol, OBD2 can achieve data rates up to 1 Mbps, facilitating faster diagnostics.

- KWP2000: Typically operates at slower speeds, up to 10.4 kbps over the K-Line, which may result in longer diagnostic times.

- OBD2: When using the CAN protocol, OBD2 can achieve data rates up to 1 Mbps, facilitating faster diagnostics.

- Diagnostic Capabilities:

- OBD2: Primarily focuses on emissions-related diagnostics and provides standardized access to various vehicle parameters.

- KWP2000: Offers more in-depth diagnostic functions, including ECU reprogramming, actuator testing, and access to manufacturer-specific data .

- OBD2: Primarily focuses on emissions-related diagnostics and provides standardized access to various vehicle parameters.

- Vehicle Compatibility:

- OBD2: Universally adopted in vehicles manufactured after the mid-1990s, ensuring broad compatibility.

- KWP2000: Commonly found in European and some Asian vehicles, particularly those produced before the widespread adoption of the CAN protocol.

- OBD2: Universally adopted in vehicles manufactured after the mid-1990s, ensuring broad compatibility.

Practical Implications

For technicians and enthusiasts working with older vehicles, especially European models, familiarity with code KWP2000 is essential. While OBD2 provides a standardized diagnostic interface, KWP2000 enables deeper access to vehicle systems, facilitating comprehensive diagnostics and maintenance tasks.

Common Applications of KWP2000 in Vehicle Diagnostics

1. Reading and Clearing Diagnostic Trouble Codes (DTCs)

One of the primary uses of code KWP2000 is to access and manage Diagnostic Trouble Codes (DTCs). Technicians can retrieve stored fault codes from Electronic Control Units (ECUs), which are essential for identifying issues within vehicle systems. After addressing the underlying problems, these codes can be cleared to reset the system. This functionality is crucial for maintaining vehicle health and ensuring compliance with emission standards.

2. Real-Time Data Monitoring

KWP2000 facilitates real-time monitoring of various sensor data, allowing technicians to observe live parameters such as engine speed, coolant temperature, and oxygen sensor readings. This capability is invaluable for diagnosing intermittent issues and verifying the performance of vehicle systems under different operating conditions.

3. ECU Identification and Configuration

Through code KWP2000, diagnostic tools can retrieve detailed information about ECUs, including part numbers, software versions, and configuration settings. This information is essential for ensuring compatibility during repairs or replacements and for maintaining accurate service records.

4. Actuator Testing and Component Activation

KWP2000 allows for the activation of specific actuators and components within the vehicle, such as fuel injectors, cooling fans, or ABS valves. This function helps in verifying the operation of individual components without the need for extensive disassembly, thereby streamlining the diagnostic process.

5. ECU Reprogramming and Software Updates

The protocol supports the reprogramming of ECUs, enabling the installation of software updates or calibration data. This is particularly important for addressing known issues, improving performance, or updating emission control strategies. The process involves secure data transfer and verification to ensure the integrity of the updates.

6. Input/Output Control and Signal Simulation

KWP2000 provides services to control and simulate input/output signals within the vehicle’s ECUs. For example, technicians can simulate sensor inputs to test ECU responses or control outputs to verify actuator functionality. This level of control is essential for in-depth diagnostics and system validation.

7. Routine Control and Special Functions

The protocol enables the execution of predefined routines within ECUs, such as system resets, adaptations, or calibrations. These routines are critical for initializing new components, adapting systems after repairs, or performing specific tests required during maintenance procedures.

Transition from KWP2000 to UDS: The Evolution of Diagnostic Protocols

The automotive industry has been transitioning from KWP2000 to Unified Diagnostic Services (UDS), standardized as ISO 14229. UDS offers enhanced diagnostic capabilities, including improved session control, security features, and support for more complex data structures. This evolution reflects the increasing complexity of vehicle systems and the need for more robust diagnostic protocols.

Troubleshooting KWP2000 Communication Issues

Troubleshooting communication issues with the code KWP2000 protocol requires a systematic approach, as various factors can disrupt the connection between diagnostic tools and a vehicle’s Electronic Control Unit (ECU). Below is an elaborated guide to identifying and resolving common KWP2000 communication problems:

1. Verify Physical Connections and Power Supply

Begin by ensuring that the diagnostic tool is properly connected to the vehicle’s OBD-II port. Inspect the connector for bent or corroded pins, and confirm that the tool receives power—typically through pin 16 of the OBD-II connector. A blown fuse associated with the diagnostic link connector can prevent communication. For instance, in some vehicles, a faulty fuse can disrupt the power supply to the ECU, leading to communication failures.

2. Confirm Diagnostic Tool Compatibility

Not all diagnostic tools support the KWP2000 protocol. Ensure that your tool explicitly lists KWP2000 or ISO 14230 among its supported protocols. Using an incompatible tool can result in failed communication attempts. Additionally, some tools may require specific software configurations or drivers to interface correctly with certain vehicle models.

3. Check Initialization Procedures

KWP2000 communication over the K-Line requires proper initialization sequences. There are two primary methods:

- 5-Baud Initialization: A slow initialization method where the tester sends a specific address at 5 baud to wake up the ECU.

- Fast Initialization: A quicker method involving a specific wake-up pattern on the K-Line.

If the diagnostic tool does not perform the correct initialization sequence, the ECU may not respond. Some ECUs are sensitive to the timing and format of these sequences, and incorrect initialization can lead to communication failures.

4. Address ECU-Specific Communication Requirements

Certain ECUs may have unique communication requirements or may not respond to standard KWP2000 queries. For example, attempting to communicate with a non-engine ECU using engine-specific diagnostic commands can result in failed connections. It’s essential to ensure that the diagnostic tool is configured to communicate with the correct ECU and that the ECU supports the requested diagnostic services.

5. Inspect for Aftermarket Modifications

Aftermarket installations, such as custom stereos or alarm systems, can interfere with the vehicle’s communication lines. These modifications might introduce noise or alter the electrical characteristics of the K-Line, leading to communication issues. If communication problems arise after installing aftermarket equipment, consider temporarily disconnecting these devices to determine if they are the source of the issue.

6. Evaluate Signal Integrity and Baud Rate Settings

KWP2000 communication relies on specific baud rates and signal configurations. Mismatches in baud rate settings between the diagnostic tool and the ECU can prevent successful communication. Additionally, incorrect serial settings, such as parity and stop bits, can cause data misinterpretation. For instance, using 8 data bits with no parity (8N1) instead of 7 data bits with odd parity (7O1) during initialization can lead to synchronization errors.

7. Test with Alternative Diagnostic Tools or Software

If communication issues persist, try using a different diagnostic tool or software known to be compatible with your vehicle’s make and model. This can help determine whether the problem lies with the original tool or with the vehicle’s communication system. Some diagnostic software applications offer more advanced configuration options, allowing for adjustments to initialization sequences and communication parameters that might resolve connectivity problems.

By systematically addressing these areas, you can effectively troubleshoot and resolve communication issues related to the code KWP2000 protocol, ensuring reliable diagnostics and maintenance of your vehicle.

The Importance of KWP2000 in Today’s Automotive Industry

While modern vehicles are increasingly adopting newer protocols like UDS, KWP2000 still plays a critical role, especially in vehicles manufactured between the late 1990s and mid-2010s. Many models from European manufacturers like Volkswagen, Audi, BMW, and Mercedes-Benz heavily relied on KWP2000 for in-depth diagnostics.

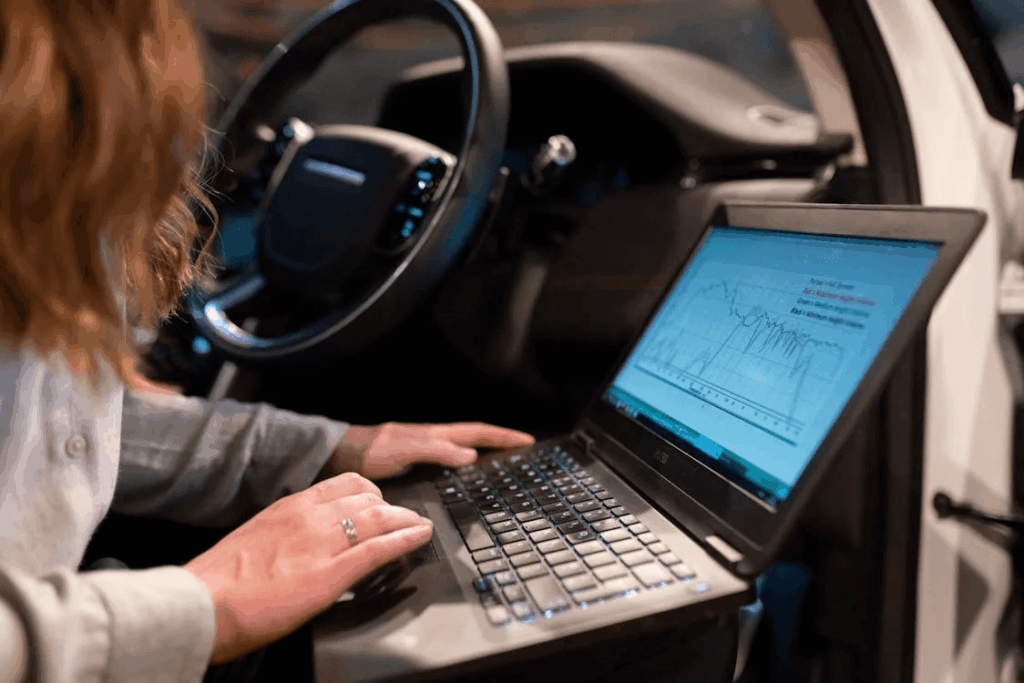

If you’re working with or purchasing a used vehicle in this category, understanding KWP2000 can give you a significant advantage. By using a compatible diagnostic tool, you can access detailed fault codes, monitor live data, and even perform limited ECU reprogramming.

Compatible Tools and Interfaces for KWP2000

To utilize KWP2000 functionality, you’ll need a diagnostic tool or software that supports the protocol. Common options include:

- OBD-II USB Interfaces with K-Line support (like the FTDI-based VAG-COM cables)

- ELM327-based scanners, though support for advanced KWP2000 features is often limited

- Professional diagnostic tools such as Autel MaxiCOM, and Launch X431, which offer full KWP2000 protocol coverage

Software applications like VCDS (VAG-COM), INPA, and KWP2000+ software also provide advanced diagnostics for enthusiasts and professionals alike.

Real-World Example: Using KWP2000 for ECU Reprogramming

Let’s say you own a 2005 Audi A4 that is experiencing inconsistent idle and throttle issues. With a KWP2000-compatible tool, you could:

- Connect to the engine control module (ECM) via K-Line.

- Retrieve DTCs using the 0x19 ReadDTCInformation service.

- Clear the fault codes after repairs using 0x14 ClearDiagnosticInformation.

- Update the ECU’s firmware or reset throttle adaptation using 0x36 ProgrammingMode.

These services demonstrate KWP2000’s versatility far beyond what standard OBD2 can offer.

Advantages and Limitations of KWP2000

✅ Advantages

- Broad Manufacturer Adoption: Supported by many European, Asian, and some American vehicles.

- Robust Services: Access to a wide range of diagnostic and programming features.

- Custom ECU Access: Enables advanced actions like configuration changes and firmware uploads.

❌ Limitations

- Slower Data Speeds: K-Line implementations are limited to 10.4 kbps, making data retrieval slower compared to CAN-based protocols.

- Obsolescence Risk: Modern cars now predominantly use UDS over CAN or Ethernet.

- Complex Initialization: K-Line wake-up sequences can be sensitive and difficult for non-professional tools.

Understanding both the strengths and the drawbacks of code KWP2000 will help you choose the right vehicles and diagnostic approaches.

Future Trends: Beyond KWP2000

As vehicles evolve into connected, software-defined machines, traditional protocols like KWP2000 are slowly being replaced by more flexible solutions:

- UDS (ISO 14229): Offers enhanced features like session control, detailed security mechanisms, and faster communication speeds.

- DoIP (Diagnostics over IP): Enables diagnostics via Ethernet, which is faster and more scalable.

- OTA (Over-the-Air Updates): Allows manufacturers to deliver ECU software updates remotely, reducing reliance on physical diagnostic connections.

However, for vehicles still on the road today—especially budget-friendly or used models—code KWP2000 remains highly relevant. Whether you’re a DIYer or a professional mechanic, knowing how to work with KWP2000 is essential for comprehensive diagnostics.

Final Thoughts: Why KWP2000 Still Matters

Even in 2025, KWP2000 continues to be an essential protocol in automotive diagnostics. Whether you’re troubleshooting a persistent check engine light on a 2006 BMW 3 Series or updating ECU parameters on an older Mercedes-Benz, understanding this protocol gives you access to a deeper layer of diagnostic capabilities than standard OBD2.