The EOBD (European On-Board Diagnostics) DTC (Diagnostic Trouble Code) P0299 is a common code that often triggers the dreaded check engine light in vehicles equipped with turbocharged or supercharged engines. It indicates an underboost condition — meaning the turbo or supercharger is not delivering the expected pressure to the engine. This issue can lead to noticeable drops in performance and fuel efficiency, and if left unresolved, it may cause damage to engine components. In this article, we will provide a comprehensive explanation of the EOBD DTC P0299, including its causes, symptoms, diagnostics, and repair solutions.

Disclosure: we may get a commission from qualifying purchases made through affiliate links in this post but at no additional cost to you.

What Is EOBD DTC P0299?

The EOBD DTC P0299 code indicates that your vehicle’s turbocharger or supercharger system is not producing the expected boost pressure. This underboost condition is detected by the Engine Control Unit (ECU) when the actual intake manifold pressure falls below the desired level for a specified duration.

In turbocharged or supercharged engines, forced induction systems compress incoming air to increase engine power and efficiency. When these systems fail to deliver adequate boost, it can lead to reduced engine performance, poor fuel economy, and potential engine damage.

Common causes of the P0299 code include:

- Boost leaks: Cracks or loose connections in the intake system can lead to loss of pressure.

- Faulty turbocharger/supercharger components: Worn or damaged parts may hinder proper boost generation.

- Malfunctioning wastegate or actuator: These components regulate boost pressure; if they fail, underboost can occur.

- Defective sensors: Inaccurate readings from sensors like the MAP sensor can mislead the ECU.

- Low oil pressure: Insufficient lubrication can impair turbocharger function.

Addressing the P0299 code promptly is crucial to maintain engine performance and prevent further damage.

Common Symptoms of EOBD DTC P0299

1. Illuminated Check Engine Light (CEL)

One of the first indicators of a P0299 code is the activation of the check engine light on your dashboard. This light serves as a general warning and can be triggered by various issues, including underboost conditions. It’s essential not to ignore this warning, as it signifies that the engine control unit (ECU) has detected a problem requiring attention.

2. Reduced Engine Power

A noticeable drop in engine performance is a hallmark symptom of a P0299 code. You might experience sluggish acceleration, difficulty maintaining highway speeds, or a general lack of responsiveness from the engine. This occurs because the turbocharger or supercharger isn’t providing the necessary boost pressure, leading to suboptimal combustion and power output.

3. Unusual Engine Noises

If you hear hissing, whining, or rattling sounds emanating from the engine bay, it could indicate issues related to the turbocharger system. A hissing noise might suggest a boost leak, while a whining sound could point to a failing turbocharger bearing. Rattling noises may be associated with a malfunctioning wastegate or actuator.

4. Limp Mode Activation

In response to detected anomalies like underboost conditions, the ECU may engage limp mode—a safety feature designed to protect the engine from further damage. When in limp mode, the vehicle’s performance is significantly restricted:

- Acceleration is limited.

- The engine may not rev beyond 2,000 to 3,000 RPMs.

- The transmission might be locked into a single gear.

- Auxiliary systems like air conditioning may be disabled.

These limitations are intended to allow you to drive the vehicle to a service center without causing additional harm.

5. Poor Fuel Economy

An underperforming turbocharger or supercharger can lead to inefficient fuel combustion, resulting in decreased fuel economy. You might find yourself refueling more frequently, even if your driving habits haven’t changed.

6. Excessive Exhaust Smoke

A failing turbocharger can cause oil to leak into the exhaust system, leading to blue or gray smoke emitting from the tailpipe. This symptom not only indicates a problem with the turbocharger but also suggests potential damage to other engine components if left unaddressed.

7. Erratic Engine Behavior

You may notice the engine idling roughly, misfiring, or experiencing hesitation during acceleration. These behaviors can result from inconsistent boost pressure, affecting the air-fuel mixture and overall engine stability.

If you encounter any of these symptoms, it’s crucial to have your vehicle inspected by a qualified mechanic promptly. Early diagnosis and repair can prevent more severe damage and ensure your vehicle continues to operate safely and efficiently.

Typical Causes of P0299

1. Boost Leaks in the Intake System

One of the most common culprits behind the P0299 code is a boost leak. This occurs when pressurized air escapes from the intake system after the turbocharger or supercharger but before it enters the engine. Such leaks can significantly reduce the amount of air reaching the engine, leading to lower boost pressure and triggering the P0299 code.

Common areas to inspect for leaks include:

- Intercooler connections: Over time, clamps can loosen, or hoses can crack, allowing air to escape.

- Charge pipes: These metal or rubber tubes can develop cracks or become disconnected.

- Throttle body seals: Worn or damaged seals can lead to air loss.

- Intake manifold gaskets: These can degrade, especially in older vehicles.

Regularly inspecting these components and ensuring all connections are tight can help prevent boost leaks.

2. Faulty Turbocharger or Supercharger

The turbocharger or supercharger is responsible for compressing air and forcing it into the engine. If either component fails or operates inefficiently, it can result in insufficient boost pressure.

Possible issues include:

- Worn bearings: Over time, the bearings in the turbocharger can wear out, causing the turbine to wobble and reducing efficiency.

- Damaged turbine blades: Foreign objects or debris can damage the blades, affecting performance.

- Seized components: Lack of lubrication or overheating can cause parts to seize, leading to complete failure.

If the turbocharger or supercharger is suspected to be the issue, it’s essential to have it inspected and, if necessary, replaced by a professional.

3. Malfunctioning Wastegate or Actuator

The wastegate controls the flow of exhaust gases to the turbocharger, regulating boost pressure. If the wastegate becomes stuck open or the actuator fails, the turbocharger may not receive enough exhaust flow to spool up adequately, leading to underboost conditions.

Symptoms of a malfunctioning wastegate or actuator include:

- Erratic boost levels: Fluctuating or inconsistent boost pressure readings.

- Unusual noises: Whining or rattling sounds from the turbo area.

- Poor acceleration: Noticeable lag or hesitation during acceleration.

Testing the wastegate’s operation and inspecting the actuator for proper movement can help diagnose this issue.

4. Faulty Boost Pressure Sensor

The boost pressure sensor monitors the amount of air pressure in the intake manifold. If this sensor provides incorrect readings to the Engine Control Unit (ECU), it can lead to improper fuel and air mixture adjustments, causing the P0299 code to trigger.

Common issues with the boost pressure sensor include:

- Wiring problems: Damaged or corroded wires can lead to faulty readings.

- Sensor contamination: Dirt or oil can affect the sensor’s accuracy.

- Internal failure: Over time, the sensor can wear out and provide incorrect data.

If the sensor is suspected to be faulty, it should be tested and replaced if necessary.

5. Low Engine Oil Pressure

Turbochargers rely on engine oil for lubrication. If the engine oil pressure is low, the turbocharger may not receive adequate lubrication, leading to increased friction and potential failure.

Causes of low oil pressure include:

- Worn oil pump: Over time, the oil pump can wear out, reducing its efficiency.

- Clogged oil filter: A clogged filter can restrict oil flow.

- Low oil levels: Insufficient oil can lead to inadequate lubrication.

Regularly checking oil levels and ensuring the oil system is functioning correctly can prevent this issue.

6. Exhaust Gas Recirculation (EGR) System Issues

The EGR system recirculates a portion of the exhaust gases back into the engine’s intake to reduce nitrogen oxide emissions. If the EGR valve becomes clogged or stuck open, it can introduce exhaust gases into the intake manifold, disrupting the air-fuel mixture and leading to underboost conditions.

Signs of EGR system issues include:

- Increased exhaust smoke: More smoke than usual, especially at idle.

- Poor engine performance: Hesitation or rough idling.

- Check engine light: Often accompanied by other codes related to emissions.

Cleaning or replacing the EGR valve can resolve these issues.

7. Air Intake Restrictions

Any restriction in the air intake system can limit the amount of air entering the engine, affecting boost pressure. Common causes of intake restrictions include:

- Dirty air filter: A clogged air filter can reduce airflow.

- Collapsed intake hoses: Over time, hoses can collapse, restricting airflow.

- Obstructions: Debris or foreign objects can block the intake path.

Regular maintenance, including air filter replacement and hose inspections, can prevent these issues.

8. Electrical or Wiring Issues

Electrical problems, such as damaged wires or poor connections, can interfere with the operation of various components related to boost pressure, including sensors and actuators.

Symptoms of electrical issues include:

- Intermittent boost readings: Fluctuating or inconsistent data from sensors.

- Erratic component behavior: Components like actuators not responding correctly.

- Check engine light: Often accompanied by other codes related to electrical systems.

Inspecting wiring harnesses and connectors for damage and ensuring proper grounding can help identify and resolve these issues.

By understanding these common causes of the EOBD DTC P0299 code, vehicle owners can take proactive steps to maintain their turbocharged or supercharged engines, ensuring optimal performance and longevity. Regular maintenance, timely repairs, and attentive driving habits are key to preventing underboost conditions and the associated diagnostic trouble codes.

Diagnosing the P0299 Code

Diagnosing the P0299 code requires a systematic approach to identify the root cause. Here’s a step-by-step guide to help you through the process:

1. Initial OBD-II Scan

Begin by using an OBD-II scanner to retrieve the stored codes. While P0299 specifically points to an underboost condition, it’s essential to check for any additional codes that might provide more context. Codes related to sensors or other components can help pinpoint the exact issue.

2. Inspect for Boost Leaks

One of the most common causes of underboost is a boost leak. These leaks can occur in various parts of the intake system, including hoses, intercoolers, and connections between components. Over time, these parts can degrade, leading to air escaping before it reaches the engine. Visually inspect all intake components for signs of wear, cracks, or loose connections. If any are found, replace or repair them as necessary.

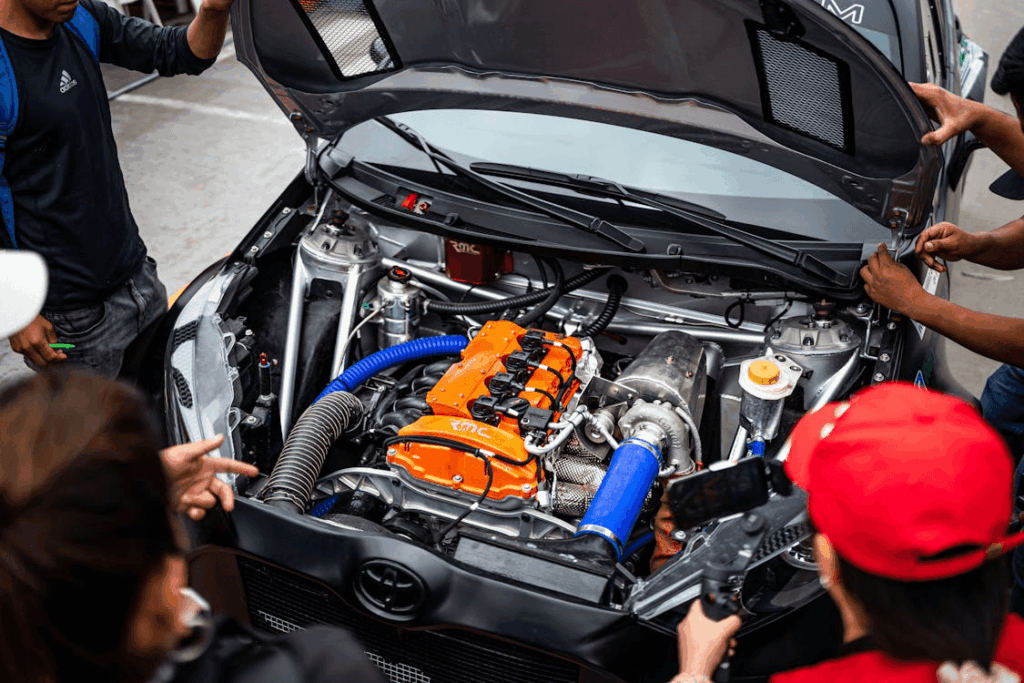

3. Evaluate the Turbocharger and Supercharger

The turbocharger or supercharger is responsible for compressing air into the engine. If these components are malfunctioning, they can lead to insufficient boost. Check for any unusual noises, such as whining or rattling, which might indicate internal damage. Additionally, inspect for oil leaks around the turbo or supercharger, as this can be a sign of seal failure.

4. Test the Wastegate and Actuator

The wastegate regulates the flow of exhaust gases to the turbocharger, controlling boost levels. If the wastegate is stuck open, it can prevent the turbo from building adequate pressure. Manually actuate the wastegate using a vacuum pump or compressed air to ensure it moves freely. If it doesn’t respond correctly, the actuator or wastegate may need replacement.

5. Assess the Boost Pressure Sensor (MAP Sensor)

The Manifold Absolute Pressure (MAP) sensor monitors the pressure within the intake manifold. A faulty MAP sensor can send incorrect readings to the Engine Control Unit (ECU), leading to erroneous underboost detection. Using a multimeter, check the sensor’s voltage output against the manufacturer’s specifications. If the readings are outside the expected range, consider replacing the sensor.

6. Examine the Boost Control Solenoid

The boost control solenoid regulates the pressure applied to the wastegate actuator. A malfunctioning solenoid can cause improper wastegate operation, leading to underboost conditions. Test the solenoid’s functionality by applying voltage and checking for proper operation. If it’s not functioning correctly, replacement may be necessary.

7. Check for Exhaust Restrictions

Restrictions in the exhaust system, such as a clogged Diesel Particulate Filter (DPF) or a blocked catalytic converter, can lead to increased backpressure, affecting turbo performance. Inspect the exhaust system for any signs of blockages or damage. Cleaning or replacing affected components can restore proper exhaust flow and boost levels.

Tools You Might Need

To effectively diagnose the P0299 code, consider having the following tools on hand:

- OBD-II Scanner: For reading and clearing diagnostic trouble codes.

- Multimeter: To check sensor voltages and continuity.

- Vacuum Pump: For testing wastegate actuators.

- Boost Leak Tester: To pressurize the intake system and detect leaks.

- Smoke Machine: Useful for identifying hard-to-find leaks in the intake system.

Repair and Fixes for EOBD DTC P0299

When your vehicle’s ECU detects that the turbocharger or supercharger isn’t delivering the expected boost pressure, it triggers the P0299 code. Here’s a comprehensive guide to diagnosing and rectifying this issue:

1. Inspect and Repair Boost Leaks

One of the most common causes of underboost conditions is a leak in the intake system. Even a small crack or loose connection in the intake hoses, intercooler, or throttle body can lead to significant power loss. Begin by visually inspecting all intake components for visible damage or wear. Utilize a boost leak tester to pressurize the system and identify any escaping air. Once identified, replace or repair the faulty components to restore proper boost levels.

2. Check and Replace the Diverter Valve

The diverter valve plays a pivotal role in redirecting excess boost pressure back into the intake system. Over time, the diaphragm within the valve can degrade, leading to improper operation. This malfunction can prevent the engine from achieving the desired boost pressure, triggering the P0299 code. If you suspect a faulty diverter valve, it’s advisable to replace it with a high-quality OEM part to ensure optimal performance.

3. Examine the Wastegate and Actuator

The wastegate regulates the flow of exhaust gases to the turbocharger, controlling boost pressure. A malfunctioning wastegate or actuator can result in the wastegate remaining open, allowing exhaust gases to bypass the turbo, leading to underboost. Inspect the actuator for signs of wear or damage. If the actuator is faulty, replacing it can restore proper boost control.

4. Assess the Boost Pressure Sensor

The boost pressure sensor monitors the amount of pressure produced by the turbocharger or supercharger. A malfunctioning sensor can send incorrect readings to the ECU, causing it to misinterpret the actual boost levels. This miscommunication can lead to the P0299 code being set. If diagnostics point to a faulty sensor, replacing it with an OEM part is recommended.

5. Evaluate the Turbocharger or Supercharger

If the above components are functioning correctly and the P0299 code persists, the issue may lie within the turbocharger or supercharger itself. Common problems include worn bearings, damaged turbine blades, or oil starvation. A thorough inspection by a professional can determine if the unit needs repair or replacement.

6. Inspect for Exhaust Leaks

An exhaust leak before the turbocharger can reduce the amount of exhaust gas available to spin the turbine, leading to insufficient boost. Inspect the exhaust manifold and associated piping for leaks. Repairing any identified leaks can restore the turbo’s efficiency and eliminate the underboost condition.

7. Check for Clogged Air Filters

A clogged air filter can restrict airflow into the engine, limiting the amount of air available for compression by the turbocharger. This restriction can lead to reduced boost pressure. Regularly inspect and replace the air filter as part of routine maintenance to ensure optimal engine performance.

8. Verify Engine Oil Levels and Quality

Turbochargers rely on engine oil for lubrication and cooling. Low oil levels or degraded oil can cause the turbo to operate inefficiently or even seize. Regularly check oil levels and quality, and replace the oil and filter as per the manufacturer’s recommendations.

9. Address EGR System Issues

The Exhaust Gas Recirculation (EGR) system reduces nitrogen oxide emissions by recirculating a portion of the exhaust gases back into the engine. A malfunctioning EGR valve can disrupt airflow, affecting turbo performance. Inspect the EGR valve for proper operation and clean or replace it if necessary.

10. Clear the ECU Codes

After addressing the underlying issue, it’s essential to clear the ECU codes to reset the system. Use an OBD-II scanner to erase the P0299 code. If the code returns after clearing, further diagnostics are needed to identify any remaining issues.

Vehicle-Specific Considerations

Ford: Ecoboost Engines

Ford’s Ecoboost engines, known for their turbocharged performance, are often associated with the P0299 code. Common issues include:

- Variable Geometry Turbo (VGT) Actuator Failures: The VGT actuator adjusts the turbo’s vanes to optimize performance. Failures can lead to insufficient boost pressure.

- Wastegate Malfunctions: A malfunctioning wastegate can prevent the turbo from reaching desired boost levels.

- Low Oil Pressure: Insufficient oil pressure can affect turbo lubrication, leading to underboost conditions.

- Faulty Boost Pressure Sensors: Inaccurate readings can mislead the Engine Control Module (ECM), triggering the P0299 code.

- Exhaust Gas Recirculation (EGR) System Issues: EGR system faults can affect engine performance and boost pressure.

For Ford vehicles, it’s crucial to inspect these components thoroughly. Regular maintenance and timely repairs can prevent the recurrence of the P0299 code.

Volkswagen/Audi: TSI/TFSI Engines

Volkswagen and Audi’s TSI/TFSI engines are prone to specific issues related to the P0299 code:

- Diverter Valve Failures: The diverter valve recirculates excess boost pressure. Failures can lead to boost leaks and underboost conditions.

- N75 Valve Malfunctions: The N75 valve regulates the turbo’s wastegate. Malfunctions can prevent proper boost control.

- Boost Pressure Sensor Issues: Faulty sensors can provide incorrect data to the ECM, triggering the P0299 code.

- Intake Leaks: Cracks or loose connections in the intake system can cause boost leaks.

For these vehicles, addressing issues with the diverter valve, N75 valve, and boost pressure sensors is essential. Regular inspections and prompt repairs can mitigate underboost problems.

Isuzu: Diesel Engines

Isuzu’s diesel engines, particularly in models like the D-Max, can experience P0299-related issues due to:

- Turbo Nozzle Control Solenoid Failures: This component regulates exhaust flow to the turbo. Failures can lead to insufficient boost.

- Fuel Delivery Problems: Issues with fuel pressure can affect turbo performance.

- Boost Pressure Sensor Malfunctions: Inaccurate readings can mislead the ECM, triggering the P0299 code.

- Induction Air Leaks: Leaks in the intake system can cause boost loss.

For Isuzu vehicles, it’s vital to inspect the turbo nozzle control solenoid, fuel system, and boost pressure sensors. Addressing these areas can resolve underboost issues and prevent future occurrences.

General Tips for All Vehicles

Regardless of the make, certain practices can help prevent the P0299 code:

- Regular Maintenance: Adhere to the manufacturer’s service intervals for oil changes, air filter replacements, and other routine maintenance tasks.

- Use Quality Fuel: Using high-quality fuel can prevent issues related to fuel delivery and combustion.

- Inspect Intake System: Regularly check for leaks or cracks in the intake system, including hoses and intercoolers.

- Monitor Turbo Performance: Pay attention to any unusual noises or performance issues related to the turbocharger.

By staying proactive and addressing potential issues promptly, you can ensure optimal performance and longevity of your vehicle’s turbocharged system.

Preventing Future P0299 Issues

Experiencing the P0299 code, indicating a turbocharger or supercharger underboost condition, can be concerning. However, with proactive maintenance and attentive driving habits, you can significantly reduce the likelihood of this issue arising again.

1. Regularly Inspect and Replace Air Filters

The air filter plays a crucial role in ensuring that clean air reaches the engine. A clogged or dirty air filter can restrict airflow, leading to performance issues and potential underboost conditions. It’s advisable to check the air filter at regular intervals and replace it as recommended by your vehicle’s manufacturer. This simple step can prevent unnecessary strain on the turbo system.

2. Maintain the Turbocharger System

The turbocharger is a vital component that enhances engine performance. Regular maintenance, such as checking for oil leaks, ensuring proper lubrication, and monitoring for unusual noises, can help detect potential issues early. Keeping the turbocharger clean and well-maintained ensures it operates efficiently, reducing the risk of underboost conditions.

3. Monitor and Maintain Oil Levels

Adequate oil levels are essential for the lubrication of the turbocharger. Low oil levels can lead to increased friction and potential damage to the turbo components. Regularly check your vehicle’s oil levels and top up as necessary. Additionally, using the recommended oil type and changing it at the intervals specified by your vehicle’s manufacturer can prolong the life of the turbocharger.

4. Inspect and Maintain Vacuum Lines

Vacuum lines control various components within the engine, including the wastegate actuator. A leak or crack in these lines can lead to improper wastegate operation, resulting in underboost conditions. Periodically inspect vacuum lines for signs of wear or damage and replace them as needed to ensure optimal engine performance.

5. Check for Boost Leaks

Boost leaks can occur in various parts of the intake system, including hoses, intercoolers, and gaskets. These leaks can lead to a loss of boost pressure, triggering the P0299 code. Conducting regular inspections and using tools like smoke machines can help identify and fix boost leaks promptly.

6. Ensure Proper Wastegate Function

The wastegate regulates the amount of exhaust gas entering the turbocharger, controlling boost levels. A malfunctioning wastegate can lead to underboost conditions. Regularly check the wastegate for proper operation and address any issues promptly to maintain optimal boost levels.

7. Maintain the Exhaust Gas Recirculation (EGR) System

The EGR system recirculates a portion of the exhaust gases back into the engine to reduce emissions. A malfunctioning EGR system can affect engine performance and potentially lead to underboost conditions. Regularly inspect the EGR system for proper operation and clean or replace components as necessary.

8. Use Quality Fuel

Using low-quality or contaminated fuel can lead to poor combustion, affecting engine performance and potentially causing underboost conditions. Always use the recommended fuel type and quality for your vehicle to ensure optimal engine performance.

9. Adopt Gentle Driving Habits

Aggressive driving can put additional strain on the turbocharger and other engine components. Adopting smooth acceleration and deceleration habits can reduce stress on the turbo system, promoting longevity and reducing the risk of underboost conditions.

10. Regularly Update Engine Control Unit (ECU) Software

Manufacturers occasionally release software updates for the ECU to improve performance and address known issues. Keeping your ECU software up to date can help ensure that the engine management system operates efficiently, reducing the likelihood of triggering the P0299 code.

By implementing these preventive measures, you can significantly reduce the risk of encountering the EOBD DTC P0299 code in the future. Regular maintenance, attentive driving habits, and prompt attention to any unusual symptoms are key to ensuring your vehicle’s turbocharged or supercharged system remains in optimal condition.

When to Seek Professional Help

While it’s tempting to tackle the P0299 code yourself, especially if you’re a DIY enthusiast, there are situations where professional assistance is not just beneficial—it’s essential.

Persistent or Recurring P0299 Codes

If you’ve cleared the code, only for it to reappear after a short drive, it’s a clear sign that the issue isn’t a minor glitch. Persistent underboost conditions often point to underlying mechanical problems, such as a failing turbocharger or a significant boost leak. These aren’t issues you want to ignore, as they can lead to more severe engine damage over time.

Complex or Specialized Repairs

Some aspects of the turbocharging system are intricate and require specialized knowledge and tools to diagnose and repair. For instance, issues with the variable geometry turbo (VGT) actuators, wastegate valves, or the turbocharger’s internal components demand expertise. Attempting these repairs without the proper skills can lead to further damage or improper fixes.

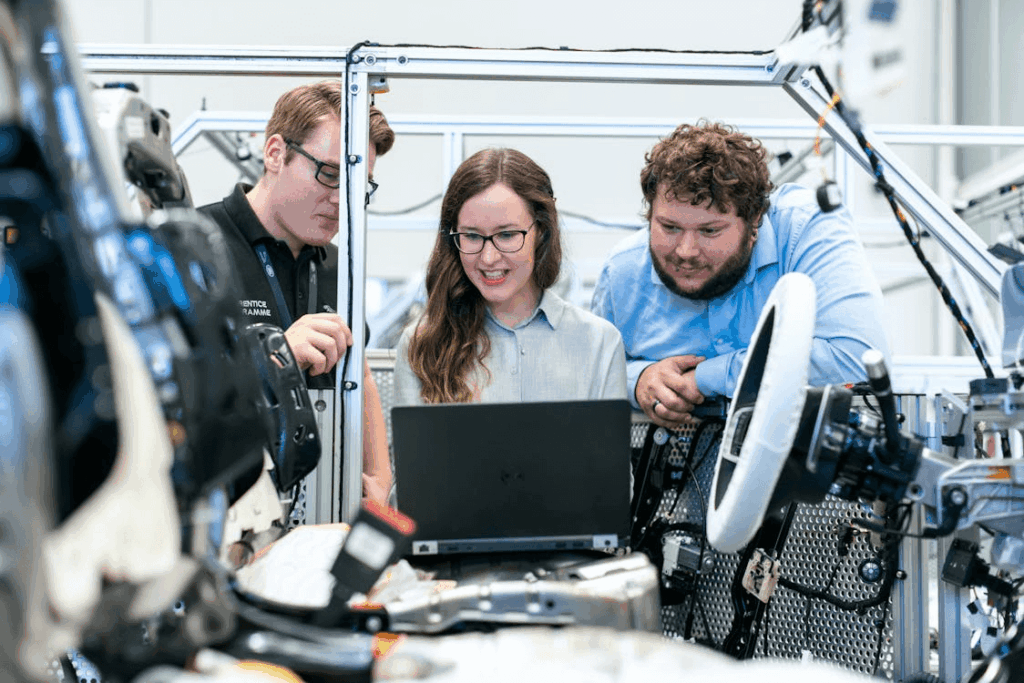

Inconclusive DIY Diagnostics

Even with an OBD-II scanner, pinpointing the exact cause of a P0299 code can be challenging. Boost leaks can be subtle, and components like the turbocharger or sensors might not show obvious signs of failure. A professional mechanic has the experience and equipment to perform comprehensive diagnostics, including pressure tests and sensor evaluations, ensuring an accurate diagnosis.

Warranty and Insurance Considerations

If your vehicle is under warranty, performing unauthorized repairs might void it. Additionally, some insurance policies require professional assessments for claims related to engine performance issues. It’s always wise to consult with a professional to avoid potential complications with warranties or insurance coverage.

Time and Cost Efficiency

While professional repairs might seem costly upfront, they can save you money in the long run. Accurate diagnostics and repairs reduce the risk of recurring issues, which can be more expensive to fix over time. Moreover, professionals can often complete repairs more quickly, getting you back on the road sooner.

If you’re experiencing the P0299 code and are unsure whether to attempt a fix yourself or consult a professional, consider the complexity of the issue, your comfort level with advanced automotive repairs, and the potential risks of further damage. When in doubt, seeking professional help ensures that the problem is addressed correctly and promptly.

Conclusion

The EOBD DTC P0299 error may seem daunting at first, but with the right approach, it can be effectively diagnosed and repaired. Whether it’s a minor boost leak or a full turbo failure, understanding the symptoms and causes is the first step in restoring your vehicle’s performance. Routine maintenance, careful driving habits, and timely repairs can help keep this code — and its consequences — at bay.

For car enthusiasts and everyday drivers alike, knowing how to handle P0299 not only preserves your engine’s health but also ensures optimal driving experience. If you suspect an underboost condition, don’t wait — inspect, diagnose, and fix it before bigger problems emerge.